| HOME | ASSEMBLY PRODUCTS | KOKI SOLDER | KOKI SOLDER SMT ADHESIVE | KOKI SOLDER WIRE | ABOUT US | LINKS | HELPFUL IDEAS | CONTACT US |

Lead Free Soldering

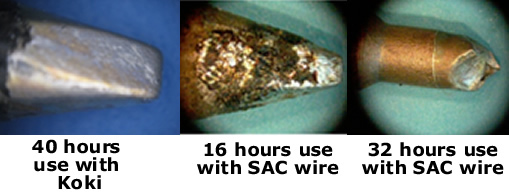

What Do Your Tips Look Like At The End Of The Week?

Follow us here to find out how we can improve performance and save you money.

Note: KOKI S0#X7Ca-56M solder wire no longer meets REACH standads and has been replaced by the 70M series.

|

Download our Linecard |

Koki JU-R2S Adhesive • It is the only non-hazardous material we know of for the application thus reducing transport costs for the end user as well as disposal costs. • The UN transport class designates competitive substances as bad for aquatic life. • It is the only know SMT adhesive that cures in the same lead free reflow profile eliminating a curing step and other process issues.

KOKI's JU-R2S solution solves this

• It has the ability to self center in the reflow process. People have been using the very old traditional chipbonders to secure heavy components for wave soldering. These older chipbonders were designed to cure by themselves at 150 degrees or so followed by wave soldering - they also all follow under the new UN class as dangerous goods for transport and disposal which can add up over to 50% of the product cost. Today, most of these applications are gone but people are still trying to use them in the new SMT processes. The new Koki product JS-R2S will eliminate the 1st curing process and will withstand the higher reflow profiles of today aside from eliminating dangerous good costs. If you are interested in examining this new product, please contact us for specifications and samples. |

|